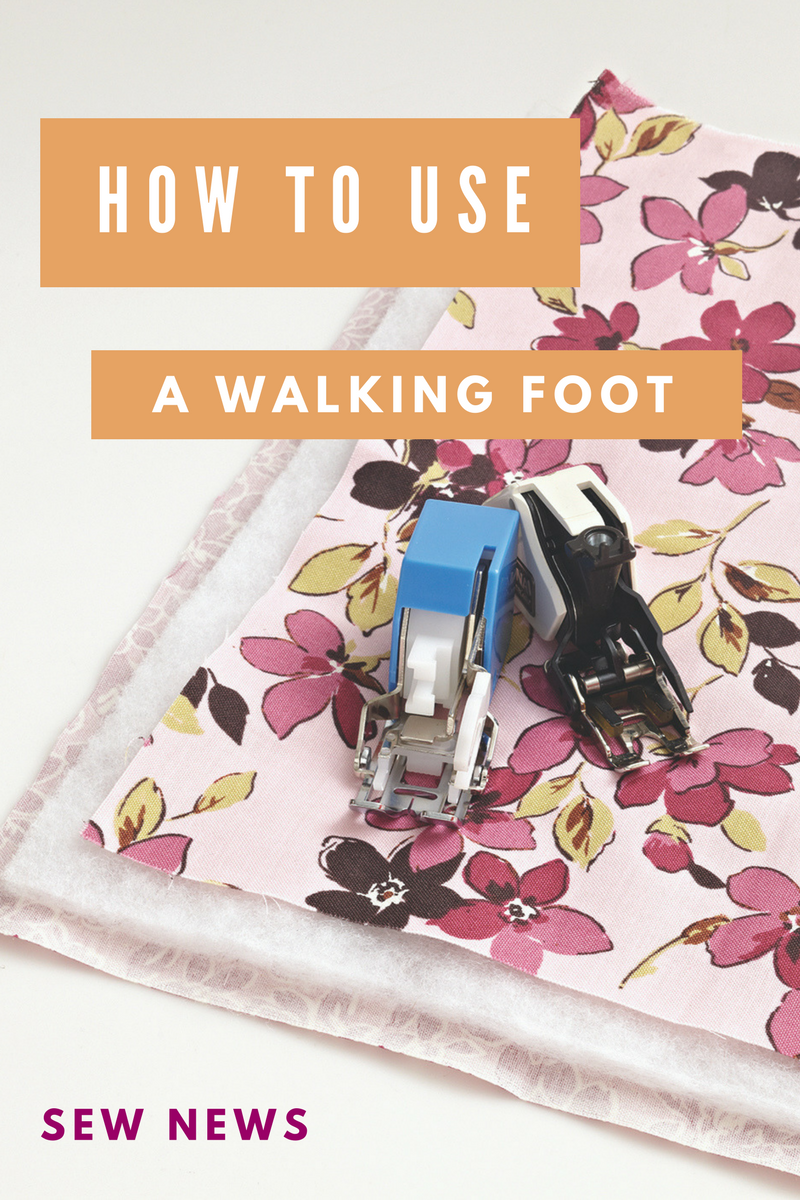

FOOTWORK: How To Use A Walking Foot

Adding a walking foot to your tool box will save your frustration some time down the sewing road. A walking foot can make a pesky job trouble free. Learn how to use a walking foot to evenly feed fabric layers for a professional finish. How to use a walking foot. When to use a walking…